Manufacturing systems process millions of operations daily with zero tolerance for downtime—energy management infrastructure controls power distribution across entire regions. Industrial automation networks coordinate complex production sequences worth millions per hour. Yet standard memory components fail under industrial use, causing system crashes that halt operations and trigger costly emergency repairs.

To avoid failure under stress, industrial-grade memory solutions require fundamentally different engineering approaches than those used in consumer electronics. Many procurement teams discover these approaches only after experiencing field failures that could have been prevented.

Let’s explore what separates industrial-grade memory from standard components, and why understanding these differences determines whether your critical systems maintain operational integrity or face unexpected shutdowns that compromise your entire operation.

Why Consumer-Grade Memory Fails in Industrial Environments

Consumer-grade memory operates effectively in controlled environments, such as office buildings, residential applications, and temperature-managed data centers. However, industrial applications subject memory components to conditions that destroy standard electronics within weeks of deployment.

Industrial environments expose memory to temperature extremes spanning -40°C to +85°C, constant mechanical vibration, electromagnetic interference from heavy machinery, power supply fluctuations, and corrosive atmospheric conditions. Consumer memory typically operates within 0°C to +70°C ranges and lacks the physical hardening, error correction algorithms, and environmental protection required for industrial durability.

Selecting consumer-grade memory based on cost savings can also lead to catastrophic system failures during peak use. Due to the production downtime, emergency replacement costs, and potential missed deliveries, the operational losses can exceed the original component savings by a large margin.

Industrial Memory Engineering Standards and Specifications

Industrial-grade memory solutions undergo rigorous qualification testing that simulates decades of harsh operational conditions. These qualification processes validate component reliability through extended temperature cycling, mechanical shock testing, vibration endurance, and electromagnetic compatibility verification.

Critical industrial memory specifications include:

- Extended Temperature Range: -40°C to +85°C continuous operation with guaranteed data retention across the full temperature spectrum

- Shock Resistance: 1500G mechanical shock tolerance with maintained data integrity and operational continuity

- Vibration Endurance: 20G RMS vibration resistance across 10Hz to 2000Hz frequency ranges without performance degradation

- Enhanced ECC: Advanced error correction algorithms capable of detecting and correcting multi-bit errors in real-time

- Extended Endurance: 100,000+ program/erase cycles compared to 3,000-10,000 cycles in consumer components

- Power Loss Protection: Integrated backup power systems that complete pending operations during unexpected power interruptions

These specifications aren’t engineering luxuries — they represent minimum requirements for memory components operating in industrial environments where failure directly impacts production output, worker safety, and operational profitability.

High-Endurance Requirements for Continuous Industrial Operations

Industrial systems generate massive data volumes through continuous monitoring, logging, and control operations that quickly exhaust standard memory endurance limits. When identifying your requirements, consider these industrial data generation patterns:

Manufacturing Systems: Quality control imaging, process parameter logging, equipment diagnostic data, and production tracking generate 50-200GB daily writes per production line. Semiconductor fabrication facilities may exceed 1TB daily writes during full production.

Energy Infrastructure: Grid monitoring systems, SCADA networks, smart meter data collection, and renewable energy optimization create continuous background write operations throughout 24/7 operational cycles.

Process Control Networks: Temperature sensors, pressure monitoring, flow rate tracking, and safety system logging produce constant data streams that require immediate storage with zero tolerance for data loss.

Consumer memory components offer 3,000-10,000 program/erase cycles before failure. Industrial-grade memory provides 100,000+ cycles with sophisticated wear leveling algorithms that uniformly distribute write operations across memory cells. This endurance difference determines whether your memory systems support 10-15 years of industrial operation or require replacement within 6-12 months.

Critical Industrial Applications for High-Reliability Memory

Manufacturing and Production Control

Modern manufacturing systems depend on real-time data processing for quality control, equipment coordination, and production optimization. These systems require memory components that maintain consistent performance under mechanical stress while supporting high-speed data logging and retrieval operations.

Manufacturing applications benefit from memory solutions with integrated power loss protection that prevents data corruption during unexpected power events. Production facilities can’t afford to lose critical process data or equipment calibration parameters due to memory failures during power disturbances.

Lexar Enterprise industrial memory solutions provide the mechanical durability and data integrity needed for manufacturing reliability. Our memory modules withstand continuous vibration from production equipment while maintaining consistent read/write performance across extended temperature ranges encountered in manufacturing environments.

Energy and Utilities Infrastructure

Energy management systems control power generation, distribution networks, and consumption optimization across vast infrastructure networks. These systems require memory components with ultra-high reliability and the ability to maintain operational continuity during environmental stress conditions.

Energy infrastructure applications demand memory solutions that operate reliably in environments where temperature variations, electromagnetic interference, and mechanical stress are constant operational factors. These could include outdoor installations, substations, and remote monitoring locations.

Grid control systems require memory components with extended endurance capabilities that support continuous data logging without degradation over decades of operation. Power utility infrastructure investments must provide 20-30 year operational lifecycles, making memory component reliability a critical selection factor.

Process Control and Automation

Industrial automation systems coordinate complex manufacturing processes, chemical reactions, and material handling operations that require precise timing and data accuracy. These systems depend on memory components that provide consistent performance without introducing delays or errors that could compromise process control.

Process control applications benefit significantly from memory solutions with advanced error correction capabilities that detect and correct data corruption in real-time. Chemical processing, pharmaceutical manufacturing, and food production require constant data integrity to maintain product quality and regulatory compliance.

Automation networks also require memory components that maintain operational stability during electromagnetic interference from motor drives, welding equipment, and high-power switching systems common in industrial environments.

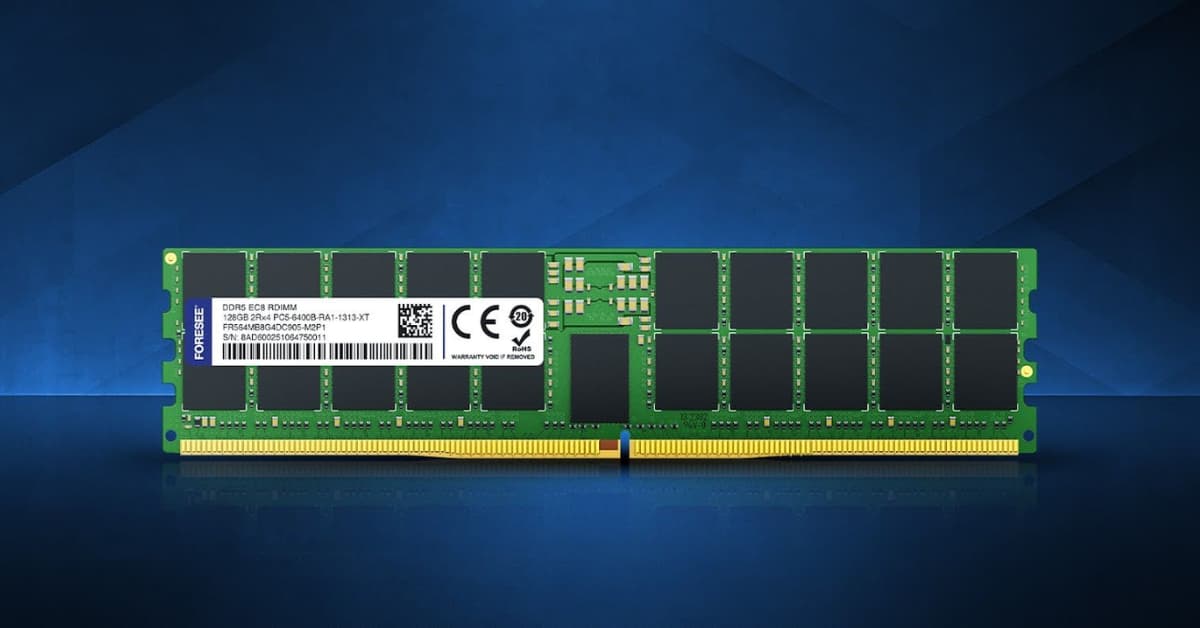

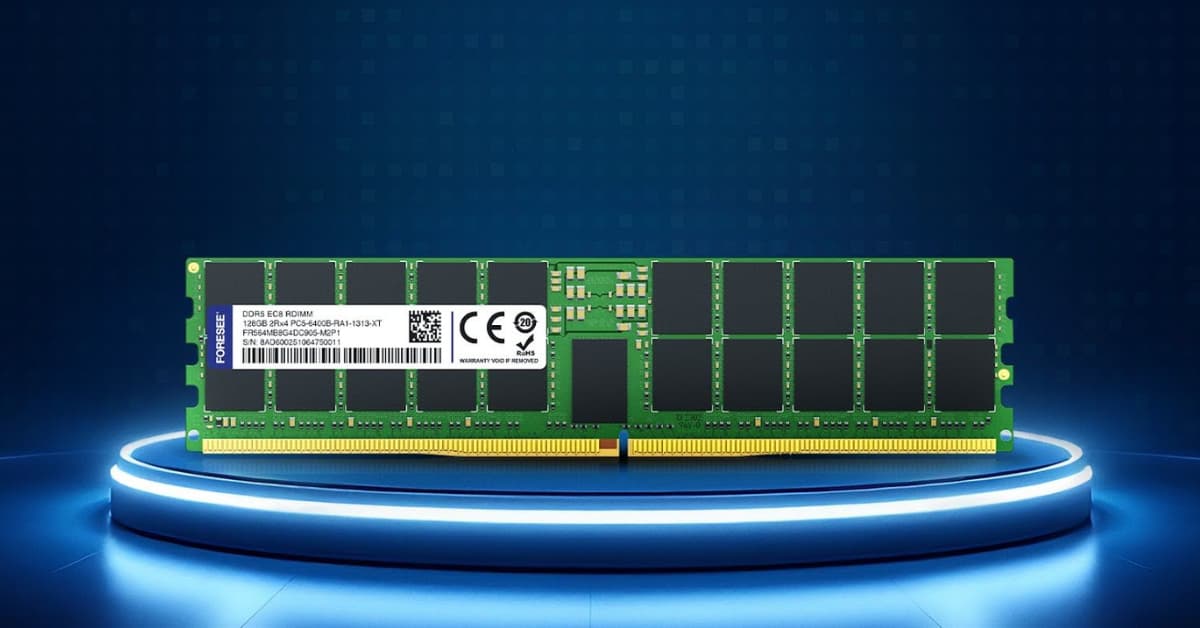

Lexar Enterprise Industrial Memory Solutions

Lexar Enterprise delivers industrial-grade memory solutions engineered explicitly for mission-critical applications. Lexar Enterprise industrial memory components address the unique challenges of harsh operating environments while providing the performance and reliability that industrial systems demand.

Industrial-Grade Specifications:

- Operating temperature range: -40°C to +85°C with extended storage ratings

- Shock resistance: 1500G mechanical shock tolerance

- Vibration endurance: 20G RMS continuous vibration resistance

- Program/erase cycles: 100,000+ with advanced wear leveling

- Enhanced ECC with real-time error correction

- Integrated power loss protection

Mission-Critical Performance Features:

- Consistent performance across the full temperature spectrum

- Advanced wear leveling for extended operational life

- Real-time health monitoring and predictive failure detection

- Electromagnetic interference immunity per industrial standards

- Conformal coating options for harsh atmospheric conditions

The Lexar Enterprise engineering team collaborates directly with industrial system integrators to optimize memory configurations for specific applications, ensuring integration success and long-term operational reliability across diverse industrial environments.

Engineering Integration Considerations for Industrial Memory

Successful industrial memory integration requires a comprehensive understanding of the interaction between memory specifications and system-level environmental conditions. Engineers must evaluate thermal management, mechanical mounting, electromagnetic compatibility, and power supply design within the broader industrial system architecture.

Thermal Management Design: Industrial memory components generate heat during operation, and this thermal energy must be dissipated effectively to maintain performance and prevent premature failure. During system design, consider heat sink design, airflow requirements, and thermal interface materials.

Mechanical Protection: Industrial environments subject memory modules to constant vibration and occasional shock events. Implement appropriate mechanical mounting systems, shock isolation, and protective enclosures that maintain memory module integrity during normal operations.

Power Supply Architecture: Industrial power systems experience significant voltage fluctuations, transient events, and occasional power interruptions. Design power supply circuits with appropriate filtering, surge protection, and backup power systems that protect memory components and maintain data integrity.

EMC Compliance: Industrial electromagnetic environments include motor drives, switching power supplies, welding equipment, and radio frequency transmissions. Select memory components with proven EMC performance and implement PCB designs that minimize electromagnetic susceptibility.

Qualification Testing and Validation Protocols

Industrial memory components require extensive qualification testing that validates performance under accelerated stress conditions. Comprehensive testing protocols include temperature cycling, mechanical stress testing, electromagnetic compatibility verification, and accelerated aging studies.

Environmental Stress Screening: Subject memory components to temperature extremes, humidity variations, and atmospheric pressure changes that simulate years of industrial operation within accelerated timeframes. This testing identifies potential failure modes and validates environmental specifications.

Mechanical Stress Validation: Test memory modules under continuous vibration, repetitive shock events, and mechanical stress conditions that exceed normal operating parameters. Mechanical testing ensures memory components maintain operational integrity throughout extended industrial service.

Electromagnetic Compatibility Testing: Verify memory performance under electromagnetic interference conditions that simulate industrial environments. EMC testing ensures memory components operate reliably near heavy machinery, power electronics, and radio frequency equipment.

Accelerated Life Testing: Memory components are operated under elevated temperature, voltage, and operational stress to predict long-term reliability. Life testing provides statistical confidence in memory component performance over projected industrial service intervals.

Memory Makes the Difference Between Uptime and Crisis

Industrial-grade memory solutions aren’t just higher-specification components—they’re the foundation for operational continuity that protects production schedules, maintains worker safety, and preserves competitive advantage in demanding industrial markets.

When you select Lexar Enterprise industrial memory solutions, you choose memory technology that withstands the harshest operating conditions, provides the endurance and reliability your systems demand, and comes with the engineering support needed for successful industrial integration. Your mission-critical operations deserve memory components that match your operational standards.

Build your next industrial system with confidence. Contact Lexar Enterprise to discuss your memory requirements and discover how our industrial-grade solutions ensure operational integrity across your most demanding applications.